#Meet The World’s Tallest 3D-Printed Tower – A Performance Space In The Swiss Alps

Coined the White Tower or Tor Alva, this majestic tower is said to be the world’s tallest 3D-printed building, and is currently being prepared for assembly in a Swiss village called Mulegns. Designed by researchers from ETH Zurich, the tower will be constructed from a hundred columns, with an impressive performance space perched on top. Created in collaboration with the cultural institution Nova Fundaziun Origen, the White Tower will be printed in different sections, then transported to the site, and assembled in the remote village in the Swiss Alps.

Designer: ETH Zurich x Nova Fundaziun Origen

The White Tower has an interesting Baroque-inspired style and will have a height of 100 meters. Massive 3D-printed columns will uphold five floors, and a semi-open facade. The facade is a removable lightweight membrane that will protect the inside of the tower from weather conditions. Visitors will be welcomed into the lower floors, which will include large columns, that form smaller cozier spaces.

The White Tower will feature a spiral staircase, that will lead them up the various floors, with each separate floor becoming visibly airier, lighter, and free-flowing, before opening into a hall on the top floor. The hall will function as a performance space for concerts and theater and will accommodate 45 visitors, including seating for them and a stage. Once the performances end, the tower will be disassembled, and rebuilt somewhere else.

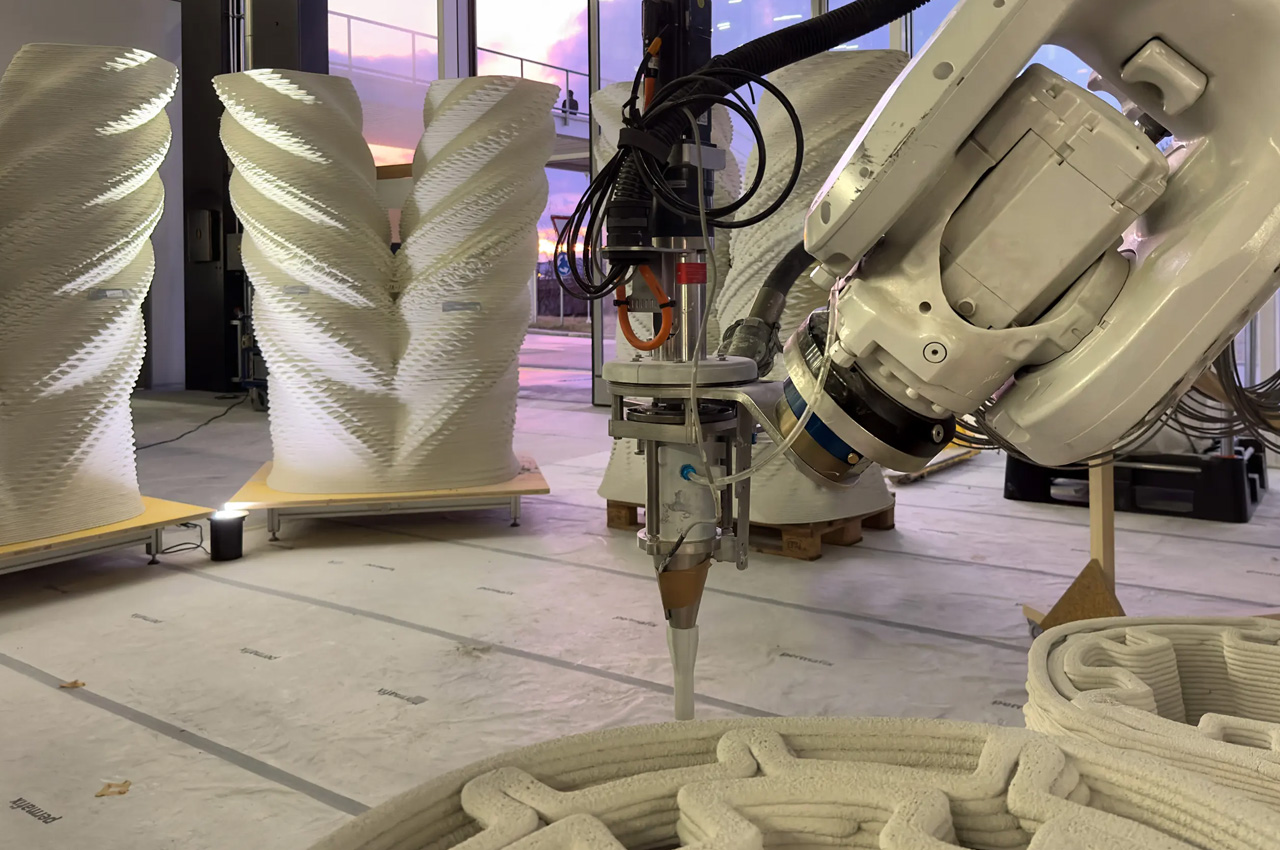

The 3D-printing process will take around 900 hours and will include robotic 3D printers that will release a soft cement-like mixture from its nozzle, extruding it in layers to form the basic structure of the different elements of the tower, which will later be assembled on-site, building the White Tower.

“The entire structure of the tower is designed using custom software that allows the precise definition of the geometry and can send the necessary data directly to the printing robots,” said ETH Zurich’s Digital Building Technologies. “This technology enables non-standard, tailor-made elements to be manufactured efficiently. These types of forms would be nearly impossible to produce at this scale using conventional technologies. In this new construction process, the tower will be assembled from 102 3D-printed individual columns. Elements are only filled with concrete where it is structurally required, which greatly reduces material use. This construction method avoids waste because no formwork for pouring concrete is necessary.”

Srishti Mitra

If you liked the article, do not forget to share it with your friends. Follow us on Google News too, click on the star and choose us from your favorites.

If you want to read more like this article, you can visit our Technology category.