#New hybrid 3D-printing technique will add a fourth dimension to additive manufacturing

“#New hybrid 3D-printing technique will add a fourth dimension to additive manufacturing”

A new chemical process for additive manufacturing suggests exciting possibilities for 4D printed components—such as properties that change over time.

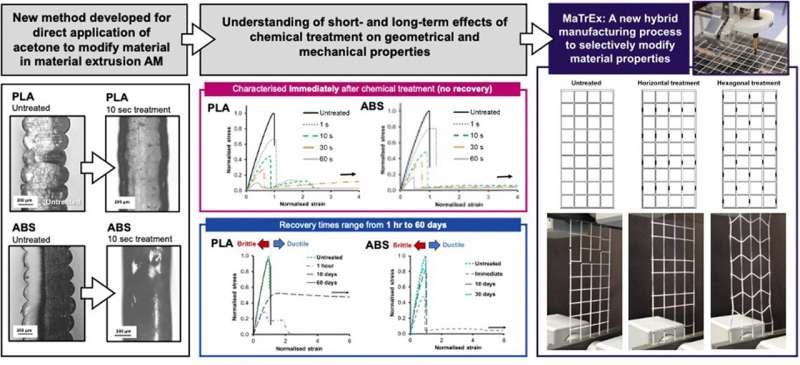

Researchers at Loughborough University have developed a hybrid method called Material Treatment Extrusion Additive Manufacturing (MaTrEx-AM), which uses acetone to toughen targeted layers of 3D printed parts and structures.

Varying how much acetone is applied and where it is used allows manufacturers to create items with novel mechanical properties, such controlling how parts deform.

The ability to create these time-dependent gives the printing process a 4D aspect.

Real-world applications include 4D lattices for helmet padding to avoid impact injuries and for biomedical implants.

Dr. Andy Gleadall said: “The process adds material layer-by-layer—there are grooves between the layers, a bit like you’d see if you stacked lot of logs sideways on top of one another, all lined up.

“3D printed parts are often weak because of the way layers are laid down in sequence, so there are geometric defects between the layers and the bonding of material between layers may not be as good as the pure polymer

“The new capabilities are potentially valuable for a huge range of parts and structures, but perhaps most obvious ones would be parts that deform during operation and the way in which they deform needs to be controlled.

“The time-dependent nature of mechanical properties means the approach adds a new dimension to material capabilities, with in-situ hybrid processing facilitating a true 4D printing process.”

The research, “MaTrEx-AM: a new hybrid additive manufacturing process to selectively control mechanical properties,” was published in the journal Additive Manufacturing.

Dynamic 3-D printing process features a light-driven twist

Amirpasha Moetazedian et al, MaTrEx AM: A new hybrid additive manufacturing process to selectively control mechanical properties, Additive Manufacturing (2021). DOI: 10.1016/j.addma.2021.102337

Citation:

New hybrid 3D-printing technique will add a fourth dimension to additive manufacturing (2021, October 11)

retrieved 11 October 2021

from https://phys.org/news/2021-10-hybrid-3d-printing-technique-fourth-dimension.html

This document is subject to copyright. Apart from any fair dealing for the purpose of private study or research, no

part may be reproduced without the written permission. The content is provided for information purposes only.

If you liked the article, do not forget to share it with your friends. Follow us on Google News too, click on the star and choose us from your favorites.

For forums sites go to Forum.BuradaBiliyorum.Com

If you want to read more Like this articles, you can visit our Science category.